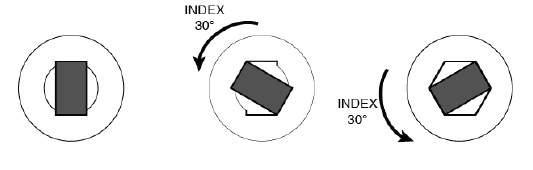

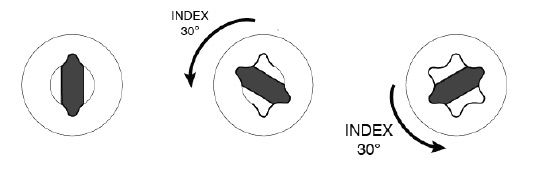

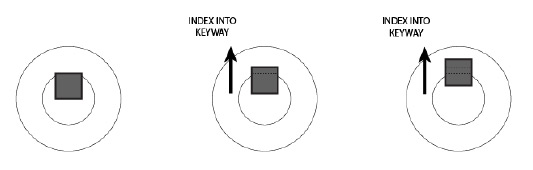

Index / Static Punch Broaching

Index punch broaching is typically used on CNC machining centers for applications:

- Where the machine cannot generate enough thrust to form the entire shape desired.

- With more stringent requirements on the straightness of the form than can be achieved with rotary broaching.

All Indexing broaches are made to order from superior Forte material to suit your application. Email sales@sommatool.com for a quote.

(203) 753-2114

(203) 753-2114  (203) 756-5489

(203) 756-5489